- en

- de

Pharma & Biopharmaceuticals Life Science

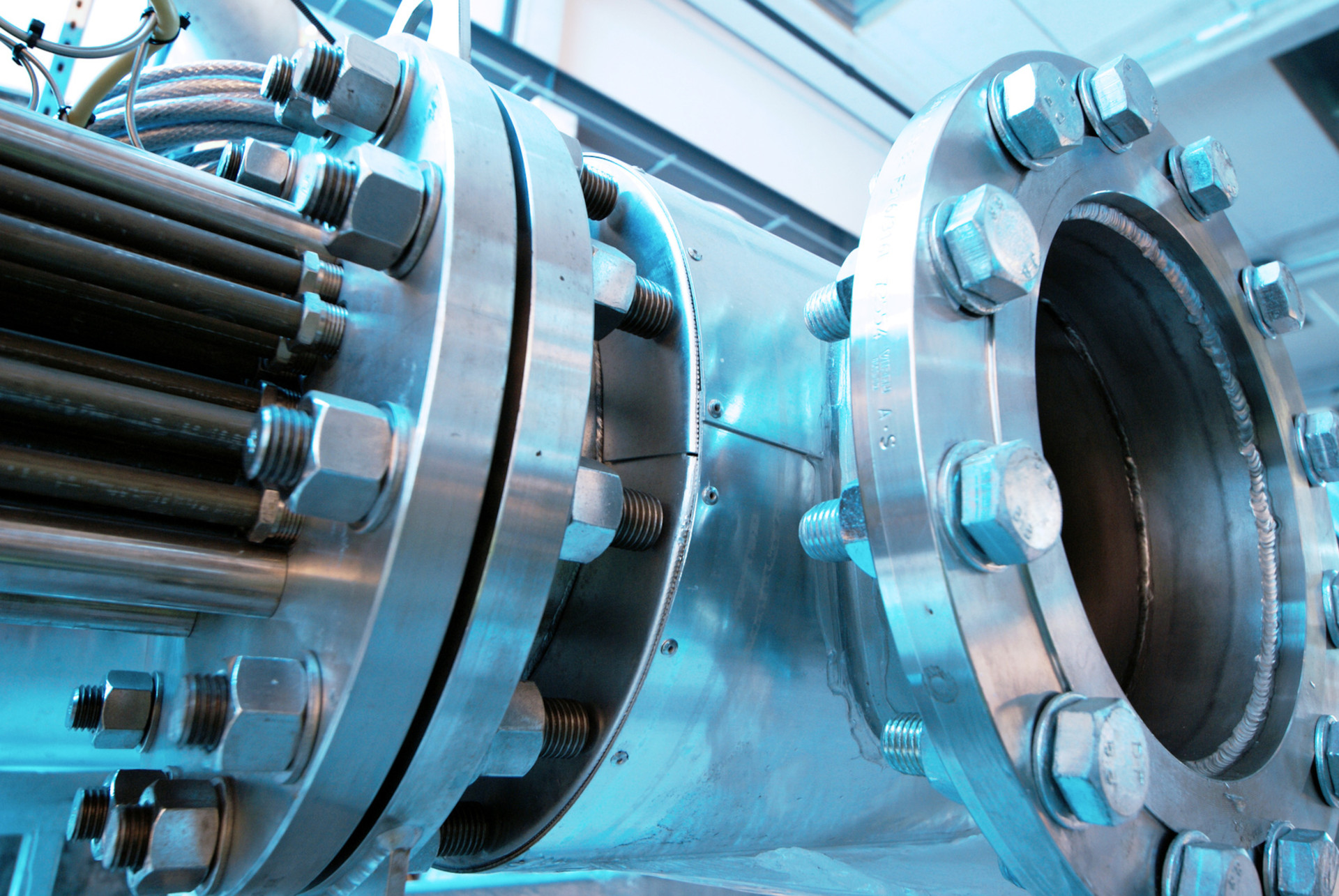

Our services for process systems

Modular plants

Increased flexibility in plant efficiency

- Improved flexibility

- Reconfigurable systems

- Accelerated design and commissioning

- Complete and uniform automation concept

- Capacity expansion through numbering UP / smart scale up

Our services in detail

We develop customized concepts for you that are perfectly tailored to the specific requirements of your pharmaceutical processes. In doing so, we take into account all relevant standards and regulations, such as GMP (Good Manufacturing Practice), as well as the individual needs of your production environment.

- Basic engineering

- Detailed engineering

- 3D laser scanning

- P&ID diagrams

- Site plans 3D visualization

- Plant construction

- Creation of specifications

- Commissioning

From the construction of production plants and cleanroom systems to cleaning systems. We supply various types of process systems for upstream and downstream applications, as well as GMP-compliant cleaning systems for the pharmaceutical and biopharmaceutical sectors. We also offer end-to-end solutions covering the entire life cycle, including R&D, engineering, manufacturing, testing, installation, qualification/validation, and after-sales support. Our quality, efficiency, and flexibility are unmatched thanks to our highly vertically integrated manufacturing.

- Process media

- Production lines

- CIP systems

- Ultrapure steam

- AP water

- Valve nodes

- WFI systems

- PW systems

After installation, we take care of the complete commissioning of your system and carry out the necessary validations in accordance with legal requirements. We ensure that all systems are functioning properly and that all quality standards are met.

Even after commissioning, we offer comprehensive maintenance and repair services. Our goal is to keep your pharmaceutical production running at a high level of performance and minimize downtime.

We implement your vision with state-of-the-art technology and maximum precision. Every system is manufactured in accordance with strict quality and safety requirements to ensure optimum production efficiency.

Industry-specific expertise

Our many years of experience in pharmaceutical plant engineering enable us to precisely understand and implement the complex requirements of the pharmaceutical industry.

GMP-compliant:

We guarantee that all plants we build comply with the highest GMP standards and meet all regulatory requirements.

Customized solutions:

Every pharmaceutical production process has its own specific requirements. That is why we develop customized solutions that are perfectly tailored to your needs.

Reliability and quality:

We attach great importance to quality and adherence to deadlines so that your production processes run smoothly and efficiently.

Sustainability:

We focus on resource-saving and sustainable solutions that are not only environmentally friendly but also economically advantageous.